For General Purposes System

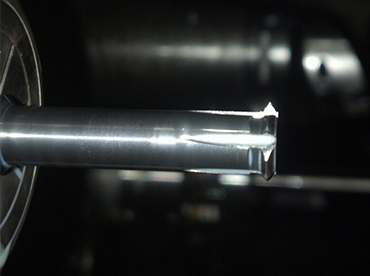

Getting high quality thread holes using threading tools is not easy. There's a high risk of damaging the tap and make it unusable.

MPSA provides its clients with an innovative approach to designing thread pieces on any type of machine tools using a CNC control system.

SwissGrade

MPSA provides its clients with advanced consulting and shares its experience in milling and threading to meet the needs of cutting tools customers. SwissGrade includes a wide range of cutting tools with its own established ranges

Fixed Part Turning

MPSA has developed the "Fixed Parts Turning" technology that produces pipes, muffs and the other connected parts based on an innovative concept. Unlike the traditional method, FPT removes the rotary movement of the facing head by CNC Control of the bar being processed. It is therefore a strong working head which rotates around the material. This innovative approach allows us to reach high quality threads' profile to guaranty our customer two crucial features assembly and sealing.

For General Purposes System

MPSA provides its clients with an innovative approach to designing thread pieces on any type of machine tools using a CNC control system.

After extensive research and analysis of the most commonly used thread cutter designs, MPSA has developed a set of two pieces of thread cutters covering most everyday needs for its customers.

Advantages:

- M and UN measuring system (60° profile)

- Reinforced design 6h5 shank diameter

- Pitch 0.5 to 3.5 mm

- For all types of material, including groups S and M

- Solid and internal coolant supply

- Available in depth 2 x D, 3 x D and up to 5 x D

This thread milling cutter duo will drastically reduce the number of threading tools used daily.

Even with a less powerful machine using SK40 spindle type, 108Nm, you will be able to simplify your threading operations. Quickly and easily usable with all types of standard basic holders with the most commonly used collets and nuts.

Our duo of thread milling tools is ideal for machining on particularly sticky Ti- or Ni- alloy pieces. Our enhanced design is specially developed to fight against the bending effect guaranteeing a final hole with straight lines preventing cone effect.

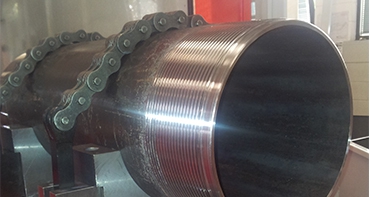

Fixed Part Turning

MPSA has developed the "Fixed Parts Turning" technology that produces pipes, muffs and the other connected parts based on an innovative concept. Unlike the traditional method, FPT removes the rotary movement of the facing head by CNC Control of the bar being processed. It is therefore a strong working head which rotates around the material. This innovative approach allows us to reach high quality threads' profile to guaranty our customer two crucial features assembly and sealing.

If we consider the range of casing pipes from 178mm to 324mm. In this cases rotating a 200-300 kg pipe is significantly complicated due to the high torque of inertia increase. To compensate this value, our competitors usually build up a strong and expensive machine only with the aim of compensating the counterforce (feedback system).

Our technical solution based on a fixed pipe and rotating cutting tools allows to turn down the weight of the pipe. "When a mass is fixed the system is easier to be controlled" – Isaac Newton.